Проектирование нефтепроводов

Проектный Институт занимается разработкой проектов систем нефтепроводов всех типов. Более 10 лет опыта.

Проектная документация строительства нефтепровода состоит из ряда разделов, количество которых может быть изменено в соответствии с требованиями заказчика. В обязательном порядке мы разрабатываем:

- планировочная организация участка;

- пояснительная записка и задание на проектирование нефтепровода;

- архитектурно-строительные и объемно-планировочные решения;

- конструктивные и объемно-планировочные решения;

- технологические решения для обустройства инженерных коммуникаций на промышленном объекте;

— проект организации строительства; - перечень мероприятий, направленных на обеспечение пожарной безопасности и охрану окружающей среды;

- смета на строительство нефтепровода.

Получите расчет проектирования вашего объекта прямо сейчас

Самые доступные цены в Санкт-Петербурге

Проект, который законно даст жизнь вашим задумкам

Схема работы с нами

Звонок или сообщение

Коммерческое предложение

Заключение договора

Разработка проекта

Готовый проект

Гарантия

Наши недавние объекты

Ликвидация опасных производственных объектов КФ АО «Апатит» АНОФ-2

«Модернизация системы теплоснабжения АО «ГСР ТЭЦ» Ижорские заводы

Ликвидация ОПО «Площадка хранения мазута и дизельного топлива пансионата «Зеленый бор»»

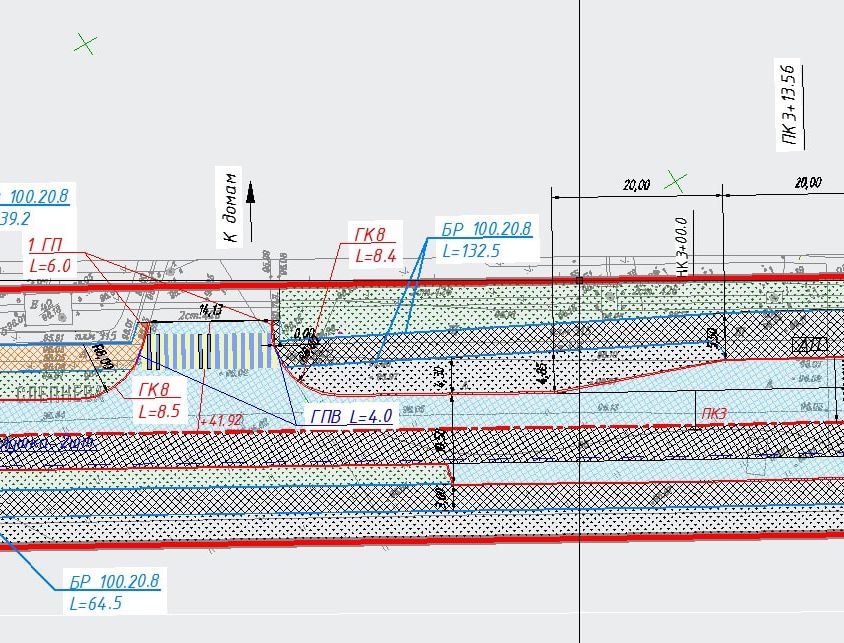

Авторский надзор «2-ой этап строительства улицы в жилой застройке в зоне II общественного центра города»

«Ликвидация опасных производственных объектов — площадок для хранения мазутного топлива котельных»

Проектирование тепловой сети Ду 250 «Пулковской ТЭЦ»

Капитальный ремонт автодороги «Москва — Санкт-Петербург» Кунино

Строительство продолжения улицы Слепнева г. Гатчина